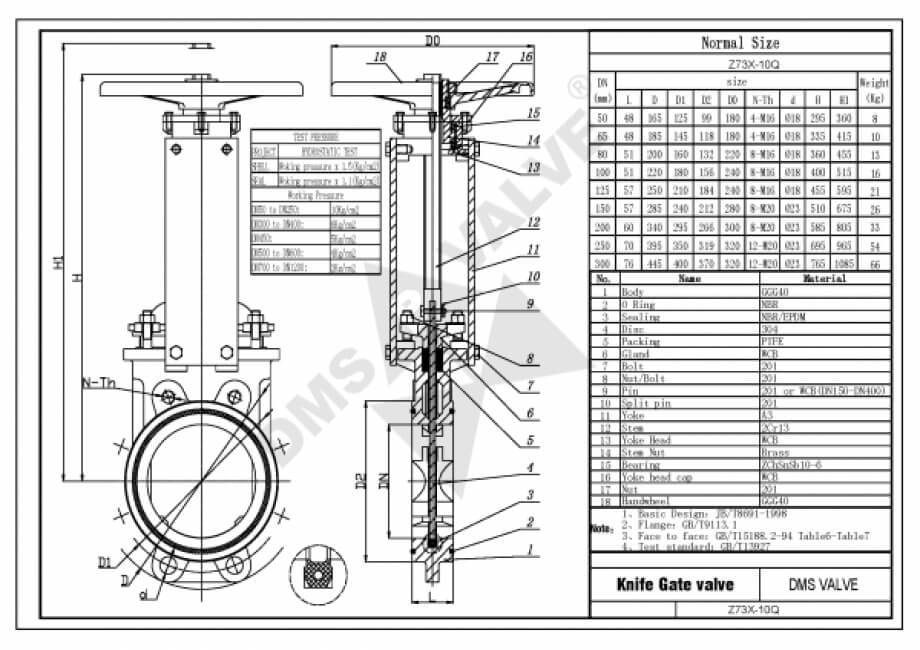

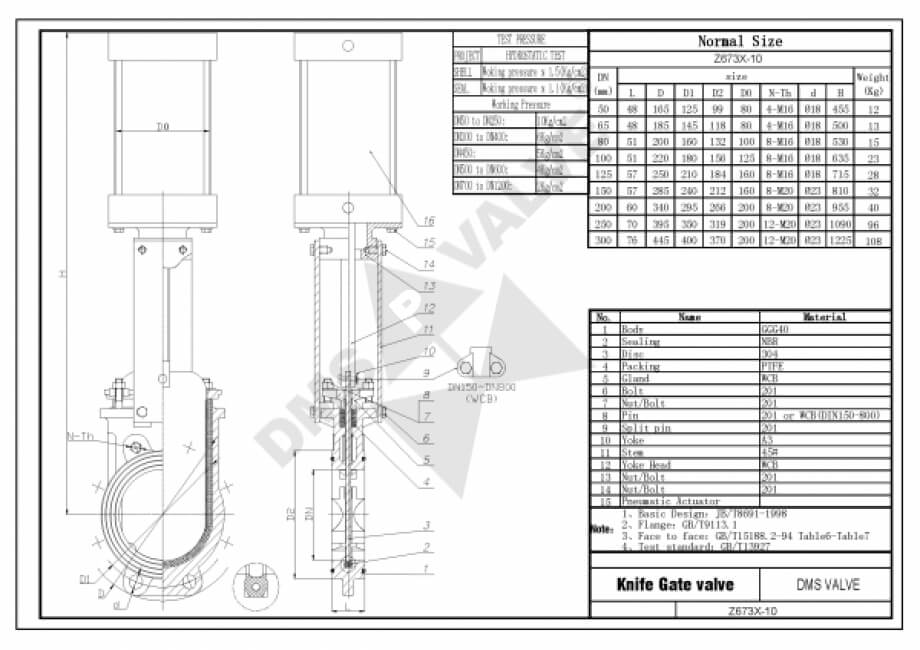

Working Method:

Gate valves; They perform their duties by closing and opening the fluid passage with a blade (slider) that slides perpendicularly to the direction of passage between two sealing rings. It is preferred that they operate fully open or fully closed. They are not suitable for precise flow control.

Areas of Use and Sealing

It is a valve type suitable for use in fibrous fluids, for example in the paper industry and waste water lines. It provides full sealing with its one-piece body and elastomer (EPDM, NBR, NR) seat. It can also be produced with a metal seat depending on its fluid properties.

It can have flywheel, gearbox, chain wheel, pneumatic actuator and electric actuator. It is available with rising and non-rising national alternatives.

Advantages:

– Fully open valve provides a very low resistance and smooth passage for the flow.

– They can be used for flow from both sides.

– The valve can be installed in any position. However, ensure that the shaft is perpendicular to the ground and the flywheel is

It is preferred to be at the top.

– Short valve length is possible even with large nominal diameters.

– They can be obtained economically and easily.

– There are types suitable for high pressures.

– It is easy to maintain.

Fluid Type:

It is preferred to be used in all fluids that we can call semi-solid.

Drive Type:

Usually manually, with pneumatic actuators

Nominal Dimensions:

It can be from DN 50 to DN 600.

Operating Temperature Range:

It is generally between -10 °C and +110 °C.

Body Material:

GGG-40 Ductile Iron

Connection:

Flange Connection/Wafer

Applications:

- Paper Industry

- Petrochemical Industry – Purification Facilities

- Mining Sector

- Chemical Production Facilities

- Food

- Control systems

TR

TR EN

EN